Scheduled Repair

Get a look behind the glove box

With 5 hours estimated (I'm slow and like to take pics) the glove box came out first after removing 9 Phillips (tool pic #2) head screws (this is a '93). The right side of the center console's panel comes off (slotted screwdriver #6, and 27 Torx #13) and the felt pad under the glove box.

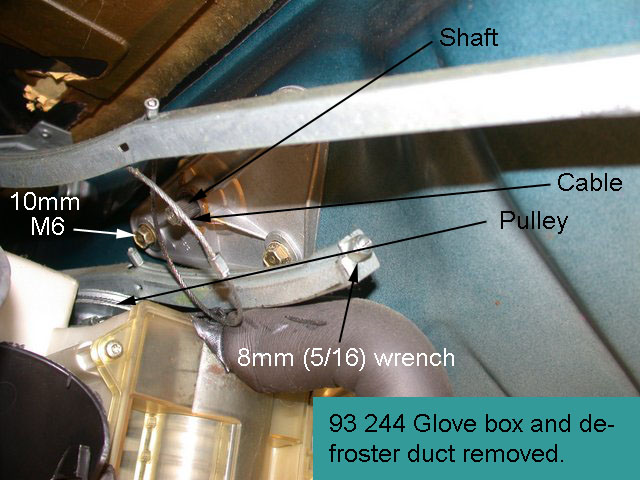

It isn't so easy seeing inside to the wiper transmission, but removing the HVAC ductwork (1 T20 screw #7) makes it easier to see what's going on. For a better look at what it is supposed to look like, and what the names of the parts are, see the main page. First thing I saw was the pulley had come off the right hand shaft, and the link arm driving it from the motor had jammed, possibly explaining why the motor was silent and hot. The motor then operates normally with the link arm unjammed.

Pulling the drive (bearing) assembly

Now, to pull the dash or try to work through the glove box opening? Easy decision. I've already pulled the dash to do this work on wiper transmissions, so this is an opportunity to try what I haven't yet done.The wiper arm with blade was removed using a 13mm wrench (#10 in the photo). The shaft pulled out even with the nut removed.

The tranmission bearing came out using 10mm tools #3,4, and #9 was especially helpful with the bolt furthest in.

The link arm disconnects from the grooved motor crank pin by pulling a clip (tool #11 to pull it and #12 to re-install it)

Fix or Replace

At this moment some more decisions needed making. Bearing assembly: Replace or repair? If repair, can the splines be bonded or should it be drilled and pinned?I could replace it (used), but we had time to repair it and no part seemed damaged beyond fixing. I decided to try bonding using a product like threadlocker, made to bond smooth shafts to inner bearing races and so forth; Loctite Retaining Compound 609. So I cleaned up the splines and the pulley with solvent (tool #14, 15), applied the adhesive and began to press the pulley on the shaft. It went on about half way before I grabbed a rubber mallet and block of wood. That got it 3/4 in before it stalled, so I took it to the little-used hydraulic press to fully seat it. If I did not have the overkill press, a large C-clamp would have done it, or perhaps a little more diligence with a brass hammer. No more worries about whether I should have pinned it. It is tight.

Putting it back in

Putting the bearing assembly back into the car, after cleaning, greasing, and renewing the body sealant, the bolts should be a turn short of tight when the alignment with the hole in the cowl and its grommet is made first.Getting it hooked up

This I anticipate will be the tough part. This is where I might regret not pulling the dash in the first place. The challenge is to connect the cables which attach the link arms to the drive pulleys. The only way I know is to disconnect one end of each (the threaded end tools #5, and #6 - a 5/16" or 8mm open end wrench) and lay the steel cable in the pulley's grooves threading the disconnected end back through the hole in the end of the link arm where the nut keeps it. I have to do this blind using memory, not having the ability to view the work at the same time as having both hands on it.It takes me a good bit of practice to get it right, using up most of the time I estimated. First the front pulley on the left side link arm, then the rear pulley on the motor drive link arm. It is done, and is all tight and smooth working without any cut, scrape, or wear damage worse than sore leg muscles. Maybe having done it before with the dash off helped, but it felt like the mistakes needed to be re-played. The loops wind around the pulleys with the loose (screw) end toward the rear of the car.

Checking it out

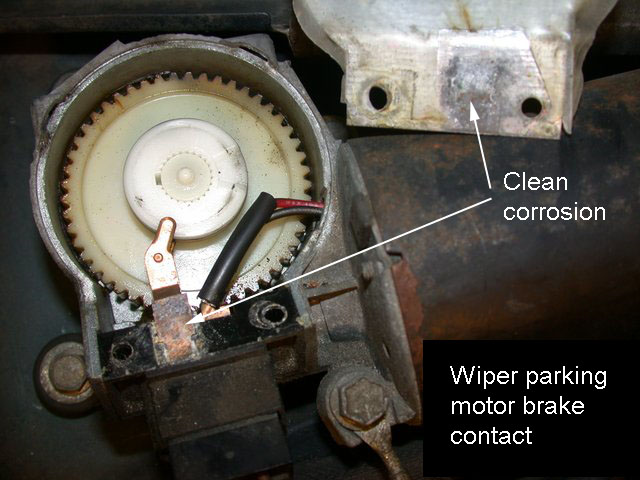

Parking problems. Bringing the wiper to parking position, by turning off at the stalk, I can hear the gears slow and then pick up again, with the left wiper blade off of the glass. I'm looking to park it so I can install the right wiper arm on the shaft, and tighten its nut. If I give it some load, by dropping the wiper blade on the glass, it does manage to park so I can align the remaining arm. But I know what causes the failure to shut off, and take care of the very common trouble by cleaning the parking brake contact (tool #15 and a bit of #1 grease). Now it parks correctly at either speed wiper blades on the glass or off.

Recap

The initial symptom, no wipers, but sounds like they're running, could result from simultaneously loose wiper arm nuts, but that would probably only occur as a result of an error of omission. The fact I could turn the wiper arms with their shafts independently proved there was no link between them. The symptom reported afterward, the wiper not shutting off (parking) was an old symptom made more evident when the link failed and removed the load from the wiper motor, making the motor brake function more obviously missing. The last symptom, the silent hot motor, was the result of the disconnected link arm falling into a jammed spot preventing the motor from turning. Since it could not park (and shut off) it would stay like that as long as the ignition key was turned on.What did I learn?

Next time (!) I'll try to pull on the wiper arm. If I would have done that day one, and the shaft came out along with it, I'd have known exactly what I'd find behind the cowl. Then I will unplug the wiper motor. And I think I'll do it from the glove box hole again, rather than pull the dash, just to see if practice helped.Return to links index

Back to wiper page