This is not a how-to. More accurately, this is a how-NOT-to. It is about some of the challenges presented by an aging 240 fuel delivery system.

There's a story to go along with the pictures, but you might want to jump ahead to some references:

Replacement Fuel Line

Terminating Fuel Line

Replacement Fitting

Here's the story. Mrs. B and I planned a drive to an "open house" put on by our daughter and son-in-law for their day camp. Grandparent duty. Because there is a Harbor Freight sorta on the way, I managed to include a stop there in the agenda.

The odor of fuel I sensed when exiting the 245 in the HF parking lot didn't alarm me at first. Lots of us DIY types bring our DIY'ed cars to Harbor Freight, but this time it was indeed strong around our car.

A peek around the left rear tire revealed a wet area on the axle and a drip. A check of the fuel gauge vs. the trip odometer (yes I use it again now, with a strong odometer gear in place) gave me the confidence to conclude we could make it home with this "slow" leak. Even keep our schedule for the day camp.

Imported tool-on-sale safely stowed, we relocated the fire extinguisher from the rear hatch area to the pasenger's floor mat and continued the trip. Next stop, I checked again, and of course the leak was worse, or so it seemed at first. Finally home, I avoided the asphalt driveway and parked on a gravel area to work on the leaky fuel system.

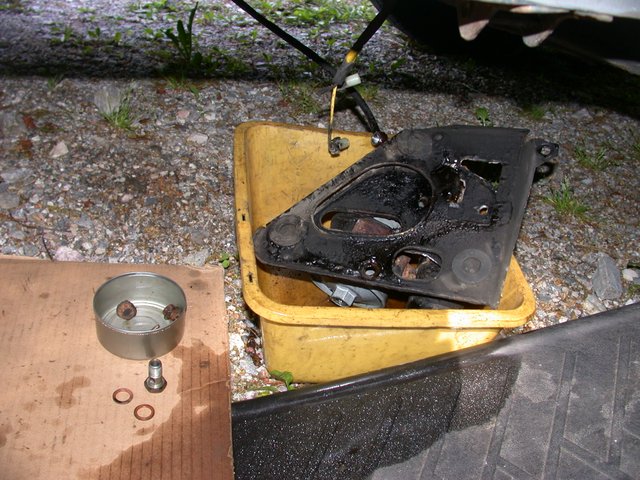

I wasn't very smart about chocking the wheels or jacking up the car. The slope was enough, I should have known better. However, I tried to use my garage tools in the gravel and wound up with the car falling off of the jack, with a jack stand pre-positioned to place under the axle. Pre-positioned right under the fuel pump and filter tray.

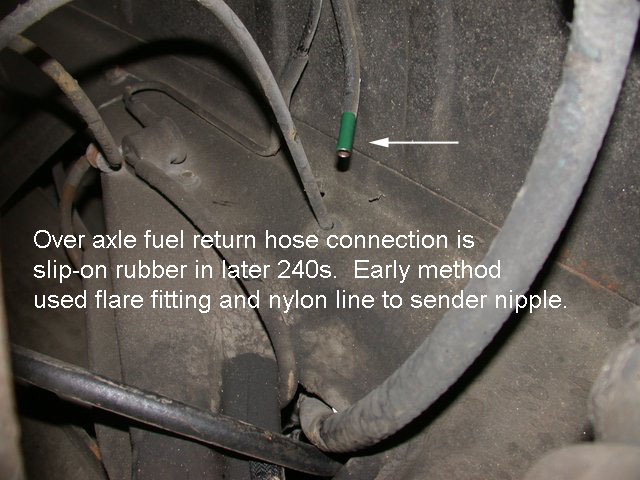

Looked like I bent the tray, so I easily straightened it with a pry bar and replaced the leaky return hose between the steel return line and the tank sender nipple.

The 245 was again sweet smelling. That is, for a few weeks. Three weeks later, Mrs. B brings it home trailing a puddle-making fuel leak and parks it on the asphalt. Oh boy, I was in trouble.

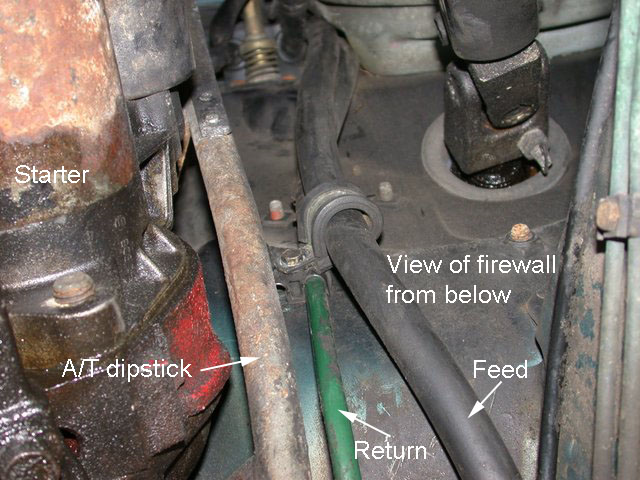

Back on the gravel with it before I even had a look, I had a sneaking suspicion I should have checked for damage after that jack fall. Sure enough, damaged high pressure line. This time I used a more substantial wheel chock.

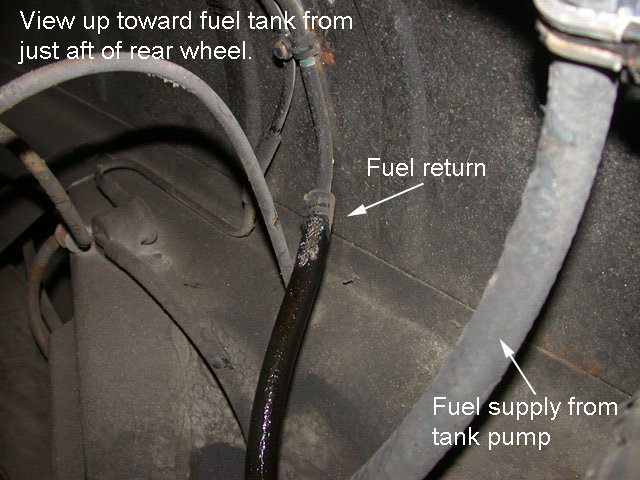

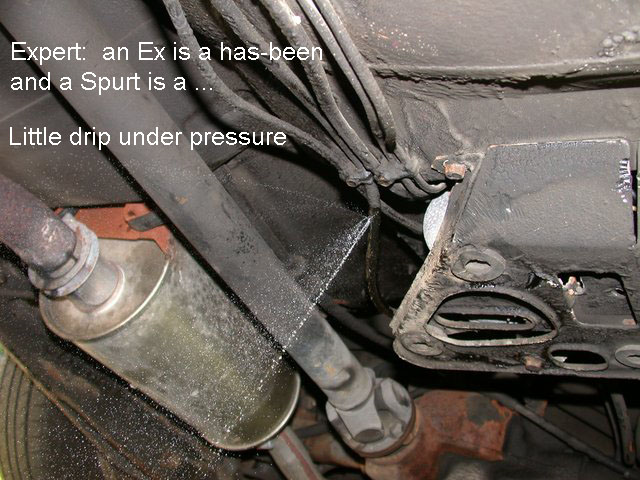

Here's the return line leak -- the original problem.

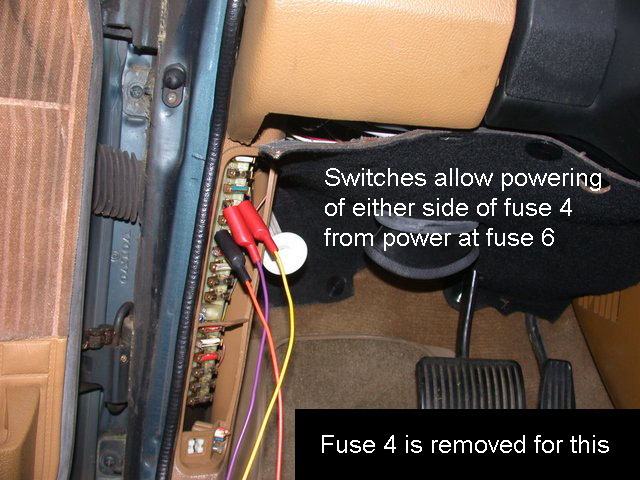

Getting the juices to flow is really simple with this handy remote control.

As smart as that may seem, is how dumb this was.

Three weeks later, the consequences of the dumb choices return to be dealt with. Ramps seem better than jacks and stands on gravel.

Watch what happens to a wet spot when the pump is turned on.

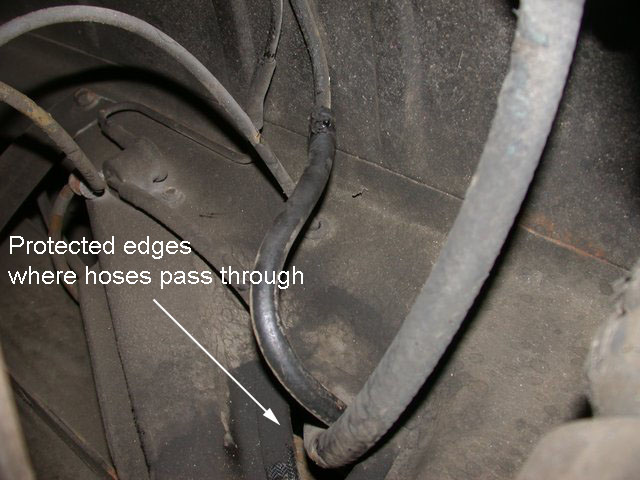

Removing the line is simply a matter of taking the clamps loose. This one large clamp is the most hidden of them.

Here is the challenge to replacing the line. Easy if you get the part from Volvo -- it comes with these ends already attached. But some are saying it is no longer available. It may be that certain lengths are available, such as for the 940 or 740, and perhaps they can be adapted, but I don't know.

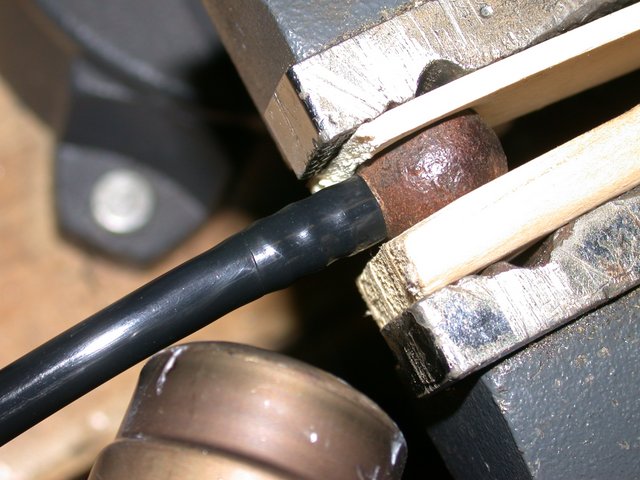

This damage was caused when the car slipped off of a floor jack being used to place a jack stand under the axle. The jack stand was positioned under the car, ready to be put under the axle, but right under the fuel pump tray.

I keep nylon line on hand. We have 8 cars - all 240 Volvos. The line I have was purchased in 25-foot lengths from McMaster-Carr, a retailer for Freelin-Wade, among thousands of other manufacturers. I could not see any difference between the metric version and the 5/16" version of this nylon line.

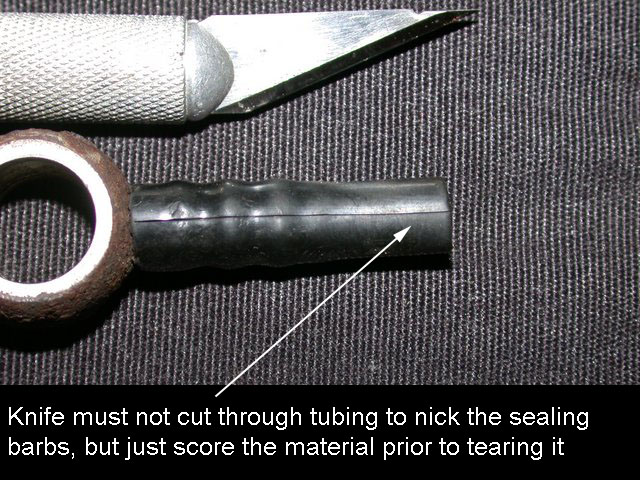

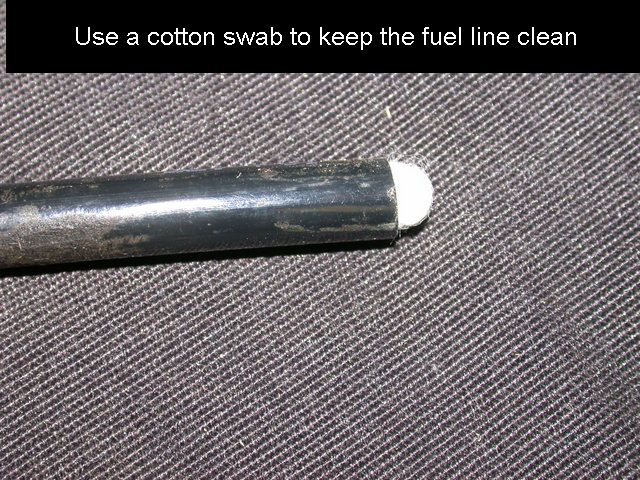

The Volvo manual suggests boiling water, I hear, but I find that inconvenient in the shop. It might be easier to control. Makes sense, because once you cut the line to length, it costs a lot to fix a botched termination.

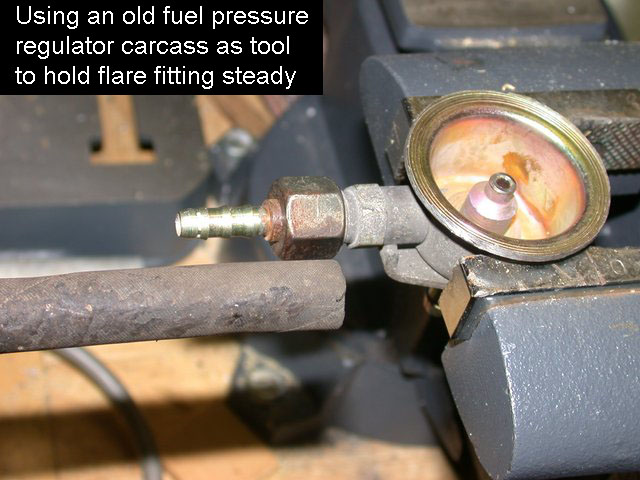

This is how I held the flare fitting -- the end that goes on the fuel rail.

And here is how I held it once, on a previous job.

I did not need to replace the banjo, but I have one in a drawer for when I do need to. They rust through, and I suppose the farther north you go, the more people you meet who have had that happen to them. This one is made by a Northerner, and I'm most appreciative.

Cheap as I am, I never have used a new washer -- here on the fuel filter, or on any of my k-jet car's fuel system hoses, nor on the power steering hydraulics. Just spend some minutes sanding the crease out of the old ones. It is an experiment. Nothing more. So far I'm winning. Or am I?

Return to links index